Ultraseal recycling technology

The complete and sustainable solution to your porosity challenges

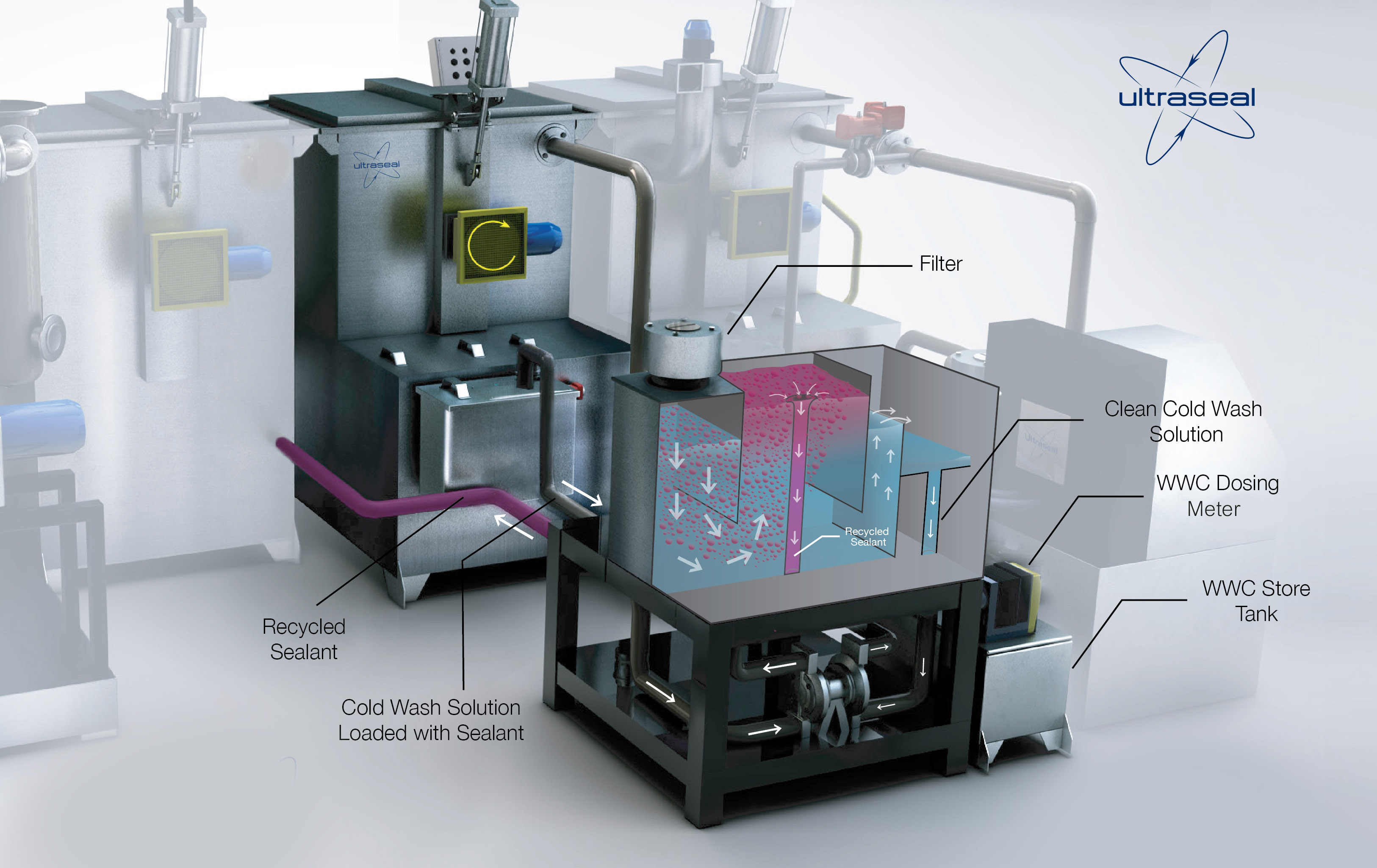

All of our impregnation systems can be specified with our market leading Ultraseal Recycling Technology and Recycling sealants, giving you best-in-class sustainability with greatly reduced sealant consumption, water consumption and effluent waste.

We also offer the option of a Hot Cure Water Recycling System to continuously recover and recycle the hot cure process water, ensuring a virtually zero effluent discharge impregnation process.

All our recycling systems are designed to maintain process water cleanliness and process quality.