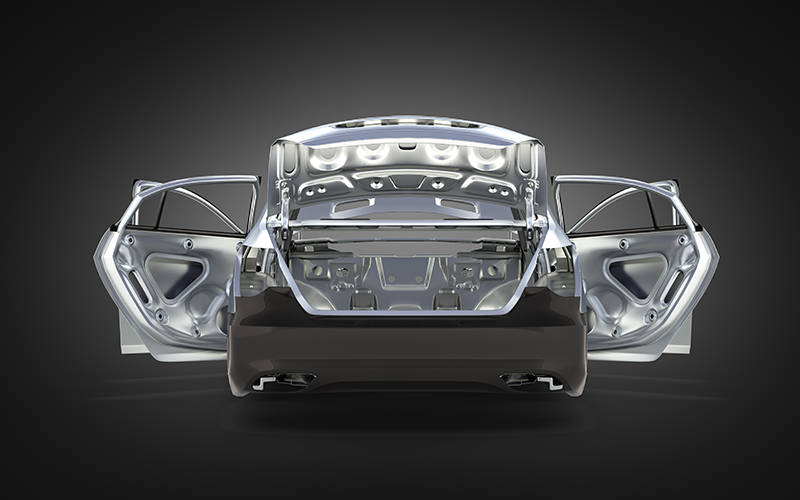

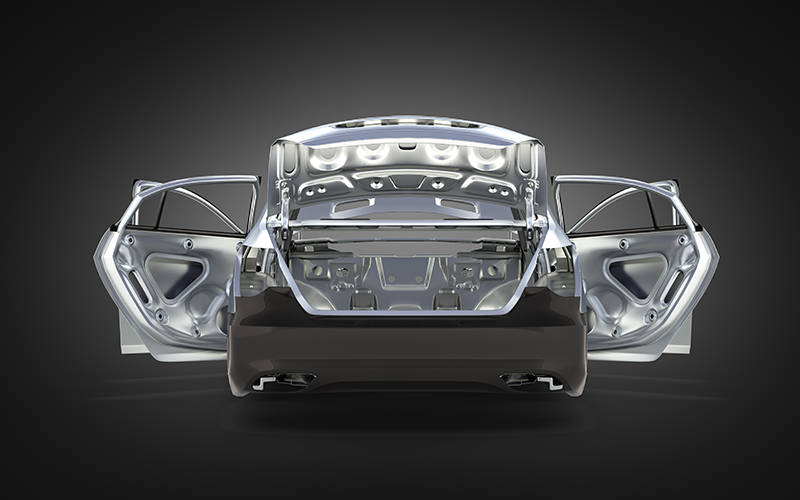

In recent years, as legislation around the world places greater emphasis on fuel efficiency, emissions and the environmental impact of vehicles, we’ve seen a shift towards light-weighting in the automotive industry. Aluminium is increasingly being used for powertrain components, alongside a rapid growth in aluminium structural components such as shock towers, rails and torque boxes.

Substituting traditionally steel components with light-weight, one-piece structures contributes significantly to reduced vehicle weights. That means greater efficiency, reduced fuel consumption and lower CO2 emissions.

Further to this, lightweight structures, and the weight reduction associated, are essential for the increasing adoption of electrified vehicles. A segment of the market forecast to grow strongly in the medium term, major OEMs are investing significantly to develop the necessary technology cost-effectively.

Developments in die-casting technology have facilitated the design of the required structural components, including larger components such as door and window frames, instrument panels and cross members. The industry has seen a trend toward larger die-casting machines and increasing shot weights.

However, the complexity of large one-piece components makes it difficult to design internal cooling which successfully reduces the temperature of all parts of the die uniformly. This can lead to localised hot spots and solder problems.

Overcoming challenges

To cast large, complex components without compromising on quality or increasing costs, it’s essential to choose a die lubricant which ensures an adequate release lubricant film is formed over the die surface.

However, the surface temperature of the die makes this difficult with water-based lubricants. To ensure the protective film is successfully formed on the die surface, some water-based lubricant will remain in the die cavities. This may cause porosity problems and water stain on the casting surface. Whilst residual water on the die surface can be dried using compressed air, this extends cycle times and is a costly consumer of electrical energy, increasing processing costs.

Using Lubrolene WFR water-free die release provides the best solution to these challenges. Significantly reducing the quantities of lubricant required, Lubrolene negates the need for die cooling by lubricant and delivers a high adhesion efficiency for thicker and more effective film formation. Quality is improved through better molten metal flow and the reduction of the quantity of trapped gases due to no external water-cool. In addition, WFR can be applied at higher temperatures than conventional water-based lubricants, meaning there is less thermal stress on dies. This avoidance of heat cracks extends the service life of the dies significantly – the major source of cost savings.

Further improvements can be seen by using Lubrolene WRF-EC – electrostatic spray technology which charges release agent particles so they are attracted to the grounded die. This creates a wrap-around effect, delivering a consistent, uniform coverage, irrespective of die complexity.

The application of Lubrolene WRF using the specially-developed electrostatic spray gun further reduces soldering problems, providing unrivalled performance.

Once the practicalities of complex, one-piece die casting are resolved through the implementation of new technologies and solutions, the benefits for automotive manufacturers begin to emerge fully.

Reduced spray time, increased die life and a low reject rate all lead to enhanced benefits and cost savings for manufacturers. Combine that with zero wastewater from the process and reduced CO2 emissions, as a result of reduced air blow, and the environmental impacts of utilising an efficient casting die release lubricant can’t be ignored.

Find out more

Discover more about Lubrolene die release agents and technology using the links below. Alternatively, for personalised information please contact our team.