Explaining casting porosity

What is porosity in casting, what are the causes, and what are the solutions?

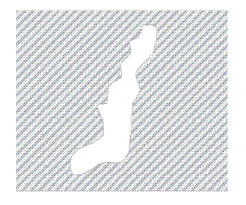

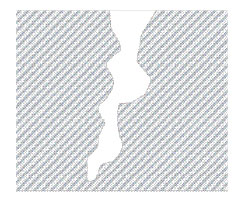

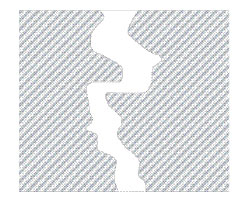

Porosity in casting refers to voids or holes in a metal component that are formed during the casting process. The phenomenon occurs as a material changes state from a liquid to a solid. Casting porosity is found in many metal components, but is especially prevalent in aluminium and magnesium die castings.