Casting impregnation

Casting Impregnation - a porosity sealing solution

Porosity is a common problem that happens during the metal casting process, and causes leak paths that would make pressure or fluid-tight parts unusable.

One way to overcome porosity, reduce down time, enhance operating costs and improve environmental performance is through vacuum impregnation, a porosity sealing solution.

To help you understand more about the casting impregnation process, we’ve answered some frequently asked questions.

What is porosity?

Porosity is a phenomenon that is caused by solidification shrinkage or gas formation when castings go from a liquid to a solid state during the manufacturing process. As a result, small imperfections and leak paths are formed which can make pressure or fluid-tight parts unusable.

What is casting impregnation?

Casting impregnation (also known as vacuum impregnation) is a porosity sealing solution that removes air from the voids then fills them with a chemically and thermally resistant polymer. For the most effective quality enhancement results, the impregnation process can be integrated within the production facility or even in-line with the manufacturing process.

How does casting impregnation work?

When a component is placed in a vacuum impregnation system, air is removed from the voids and the leak paths and porosity in the component are filled with a chemically and thermally resistant polymer sealant. Excess sealant is then drained and washed from the component and the sealant within the porosity is then cured to provide a permanent seal.

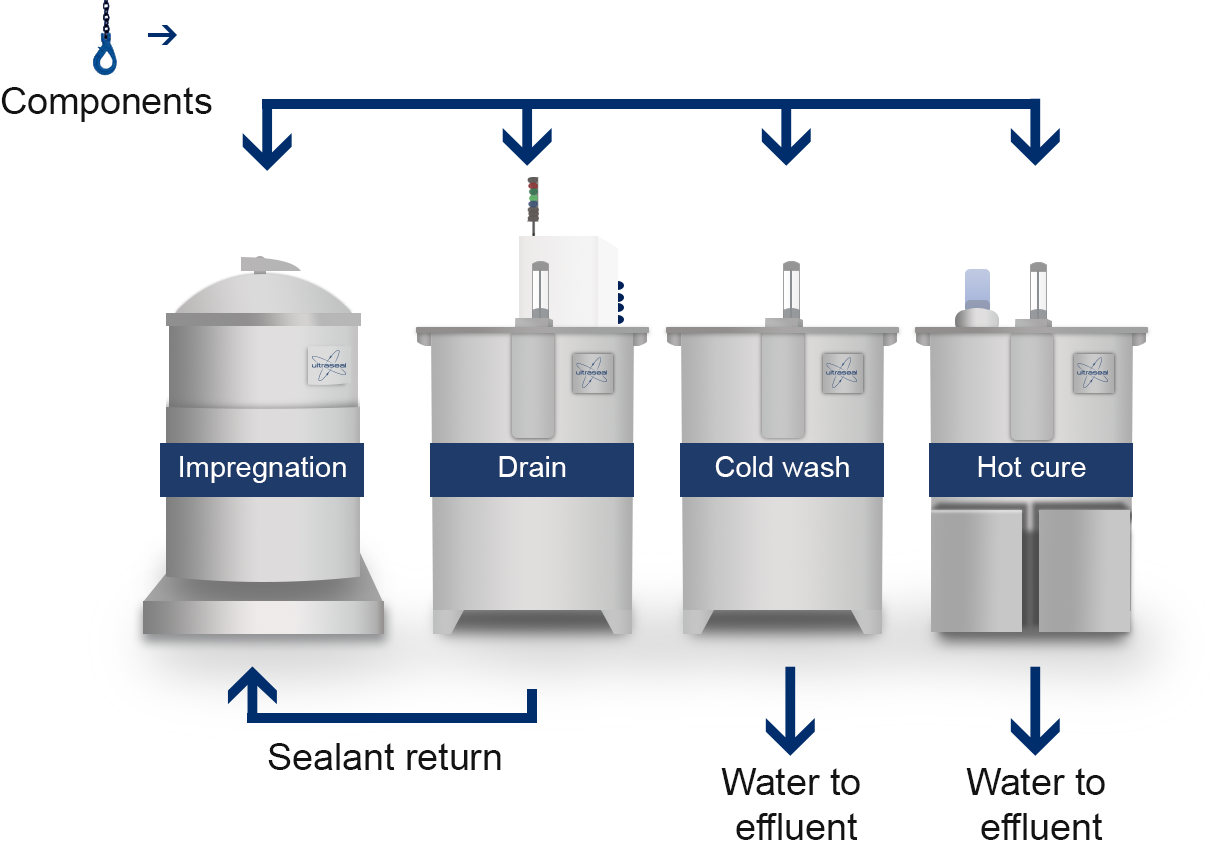

The casting impregnation process explained

1. Impregnation.

First, components are subjected to a dry vacuum in an autoclave, removing the air from the porosity. The components are then immersed in liquid sealant and the vacuum is released, filling the voids with the sealant.

2. Drain.

3. Cold Wash.

Next, a cold wash removes excess sealant from external component surfaces.

4. Hot Cure.

Finally, a hot cure cycle is used which polymerises the sealant, turning it from a liquid state to a solid polymer.

Which impregnation sealants can be used?

Ultraseal International offers two types of sealant; non-recycling and recycling sealant.

Our recycling sealant delivers exceptional performance and the lowest cost of operation, while helping tackle the challenges of effluent and waste water, making it the ultimate sustainable solution to sealing porosity in cast components. Rexeal 100 and MX2 recycling sealants continue to keep millions of cast components leak free and reliable.

We offer three types of non-recycling sealant – PC504/66, Sinterseal and Electroseal. They provide a complete solution to sealing porosity in metal castings, electronic leads and connectors, and sintered components.

We also provide a range of detergents and inhibitors developed to work specifically with Ultraseal sealants and equipment. These chemicals enhance performance and ensure consistent Ultraseal quality across both your impregnation equipment and manufacturing process. Find out more about our detergents and inhibitors.

Which applications require casting impregnation?

Vacuum impregnation is suitable for a wide range of applications, including:

Automotive Powertrain Components e.g. cylinder head, cylinder block, transmission housing, EV battery housing, electric motor housing

Braking Systems

Air Conditioning Compressors

Electrical Components

Sintered Components

Additive Manufactured/3D Printed Components

Casting impregnation services, sealants and equipment from Ultraseal International

Ultraseal International is the global leader in porosity sealing, providing casting impregnation services, sealants and equipment to meet all manufacturing requirements.

Outsourcing casting impregnation to one of our worldwide impregnation service centres is a popular solution for manufacturers with lower production volumes. Those with higher production volumes may wish to consider investing in vacuum impregnation equipment or opting for our fully managed onsite service.

There are many considerations when making an investment in equipment, such as:

Component dimensions and available system floor-space;

Whether the system is to be integrated into the existing production process or an off-line system;

Operator involvement; choice of component handling method;

Operating and environmental cost factors.

For more information about vacuum impregnation, casting impregnation or guidance on the best porosity sealing solution for your business, please get in touch with the Ultraseal team.