Semi-automated Top loading impregnation systems

Semi-automatic systems with rotational washing and superior performance

Our semi-automatic top loading systems incorporate unique rotational washing technology to ensure exceptional results.

Key Benefits

Unique Rotational Processing System Technology

Positive process solution penetration of high density workloads

Effective cascade/rotational washing action

Rotation drain provides effective recovery and re-use of process chemicals

Rotation eliminates poor treatment due to air pockets

Available with Ultraseal Recycling Technology

Autoclave System Options

Sealant Transfer System (STS)

Workload is loaded into the autoclave with sealant in an adjacent tank. After the vacuum has been drawn on the autoclave, sealant transfers into the autoclave immersing the components.

Vacuum is released, forcing the sealant into the porosity. Sealant is returned to the storage tank under vacuum. STS machines are simpler to automate and benefit from well-conditioned sealant due to length of time the sealant is held under vacuum.

Vertical Transfer System (VTS)

Workload is suspended in a basket during the vacuum phase before being lowered and immersed in the sealant. The vacuum is then released, forcing the sealant deep into the porosity.

VTS impregnation machines offer faster cycle times with a smaller footprint.

Return Vertical Transfer System (RVTS)

As with the VTS autoclave the module permits the sealant impregnation process to take place in a single module without the need for a separate sealant storage tank, thereby minimising floor space requirements.

The workload is located on the RVTS platform during the vacuum phase before being automatically lowered in to the sealant (wet vacuum phase of the impregnation cycle). The vacuum is then released, forcing the sealant deep into the porosity. At the end of the cycle the workload is automatically raised out of the sealant in readiness for removal from the process module.

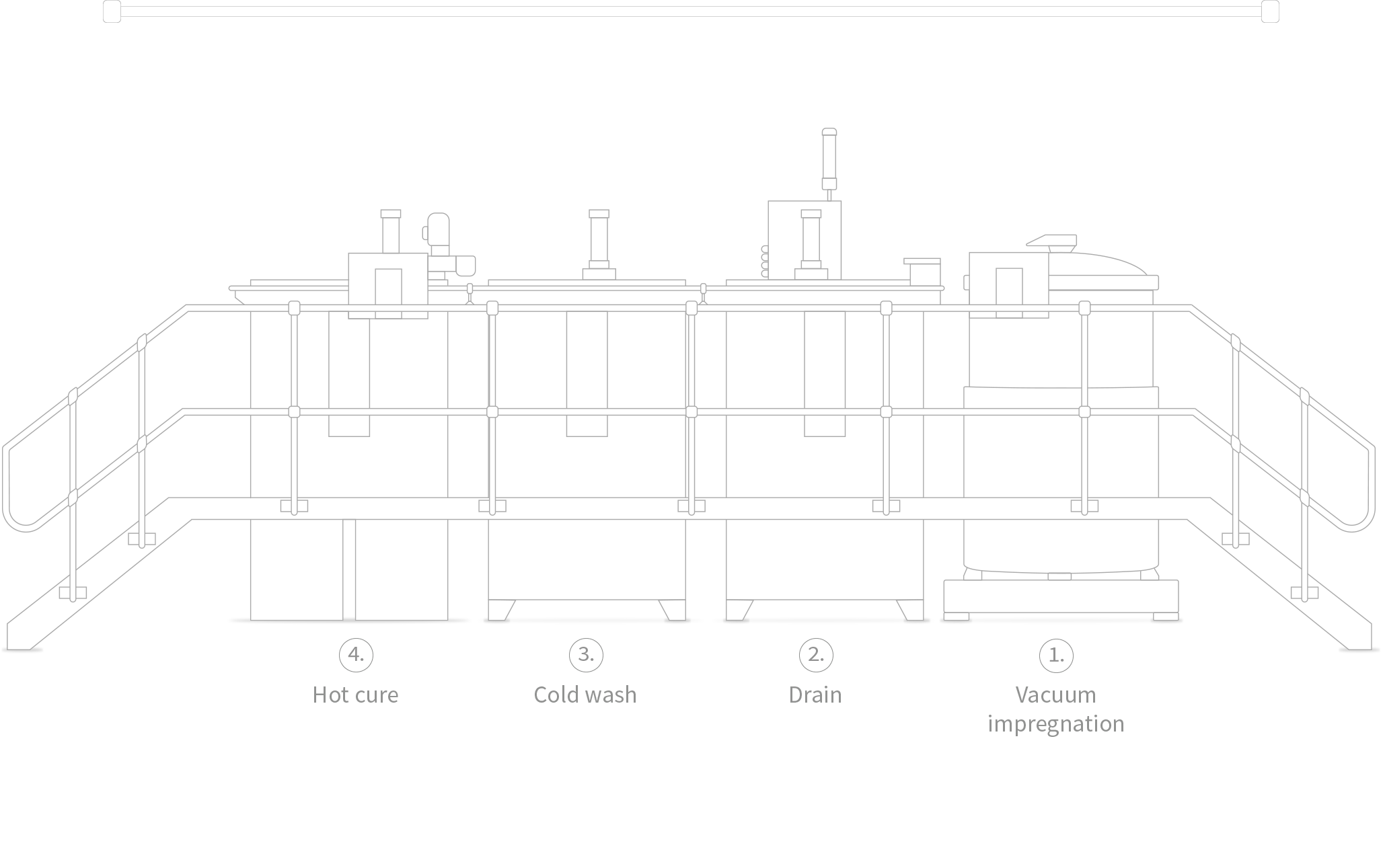

Top Loading Machine Process

Vacuum impregnation process stages:

1 Impregnation

2 Drain

3 Cold wash

4 Hot cure

'A' series specification

Options

- Vacuum or pressure impregnation

- Recycling or non-recycling system

- Overhead or cantilever gantry

- STS, VTS or RVTS

- Rotation or non-rotation

- Filtration

- Component jigging

Machine dimensions (WxDxH)

5370 x 4320 x 2520mm*

Normal load capacity

500 x 500 x 540mm

Weight capacity

120kg

'B' series specification

Options

- Vacuum or pressure impregnation

- Recycling or non-recycling system

- Overhead or cantilever gantry

- STS, VTS or RVTS

- Rotation or non-rotation

- Filtration

- Component jigging

Machine dimensions (WxDxH)

7990 x 4755 x 3530mm*

Normal load capacity

700 x 700 x 790mm

Weight capacity

300kg

'C' series specification

Options

- Vacuum or pressure impregnation

- Recycling or non-recycling system

- Overhead or cantilever gantry

- STS, VTS or RVTS

- Rotation or non-rotation

- Filtration

- Component jigging

Machine dimensions (WxDxH)

10960 x 5410 x 3500mm*

Normal load capacity

1000 x 1000 x 1000mm

Weight capacity

750kg

*all machine sizes based on a standard 4 module top load system