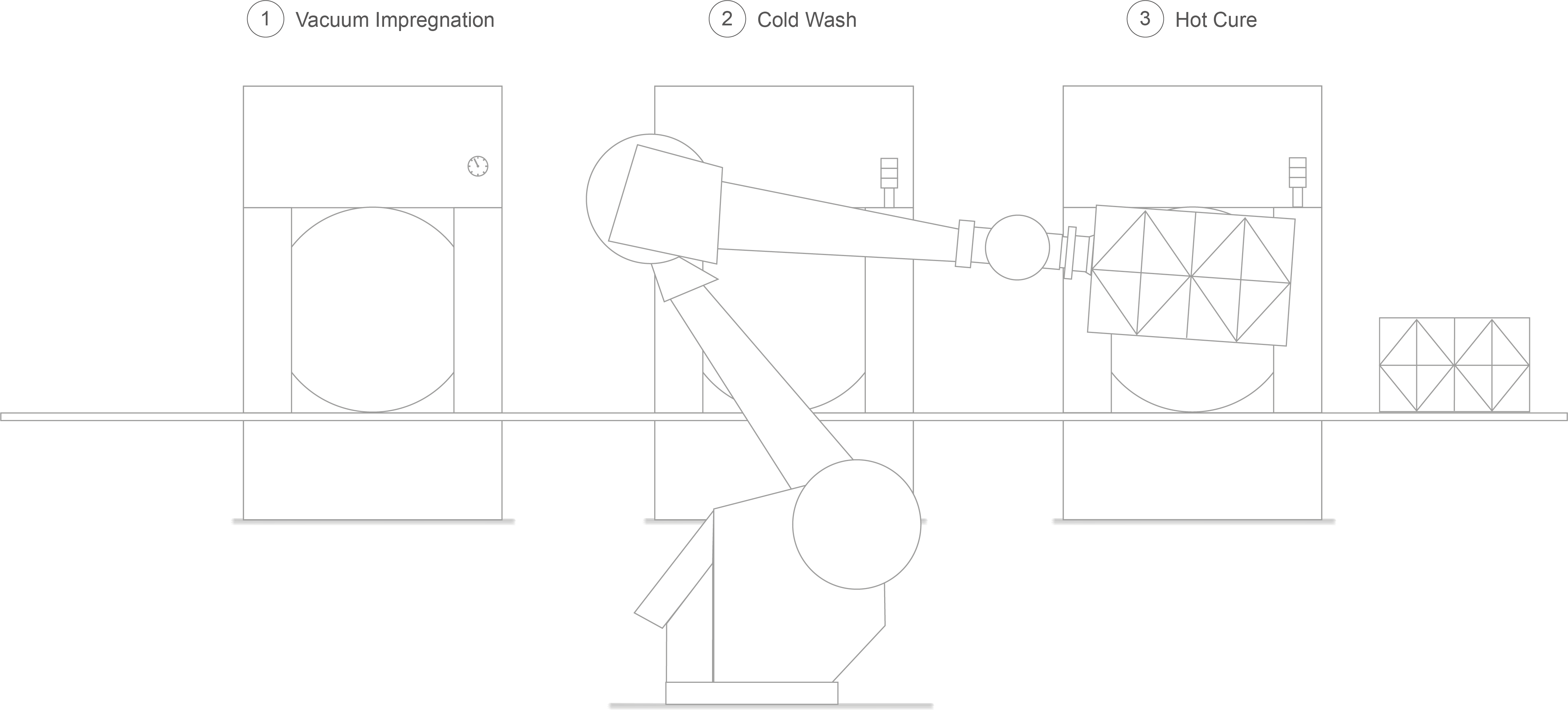

Fully automated robotic front load impregnation systems

Best-in-class systems for fast cycle times and single part processing

Ultraseal’s robotic front load vacuum impregnation systems seal components in a fast and efficient sequence, eliminating manual handling as components are moved between each module reliably and consistently.

Shorter cycle times deliver higher throughput with each module accommodating a smaller number of components – or single part processing – and so minimising work in progress.

Our robotic systems can be configured to be integrated in-line to the previous manufacturing process stage or to the next machine/process stage.