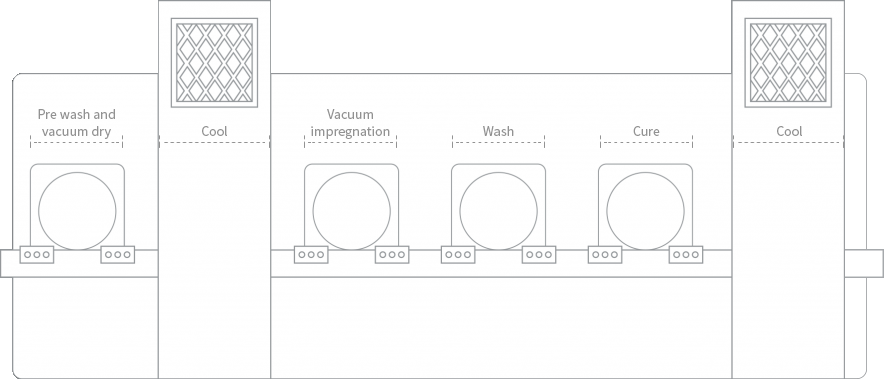

Fully automated front load systems

Best-in-class systems for faster cycle times and improved flexibility

Our best-in-class modular automated systems offer greater speed, control and significant health and safety advantages, as well as the key ability to be fully integrated into production lines.

Shorter cycle times deliver higher throughput with each module accommodating a smaller number of components and so minimising work in progress.

Each compact module offers all the productivity and quality advantages associated with rotational processing, while unlike top-loading machines, the rotational drain process takes place within the autoclave, reducing the number of modules required and so saving cost and floor-space.

A range of automated workload handling options are available including powered conveyor systems to transport components between each impregnation process module, together with a loading and unloading mechanism for each module.

Fully automated impregnation systems can be configured to be integrated in-line to the previous manufacturing process stage or to the next machine/process stage.